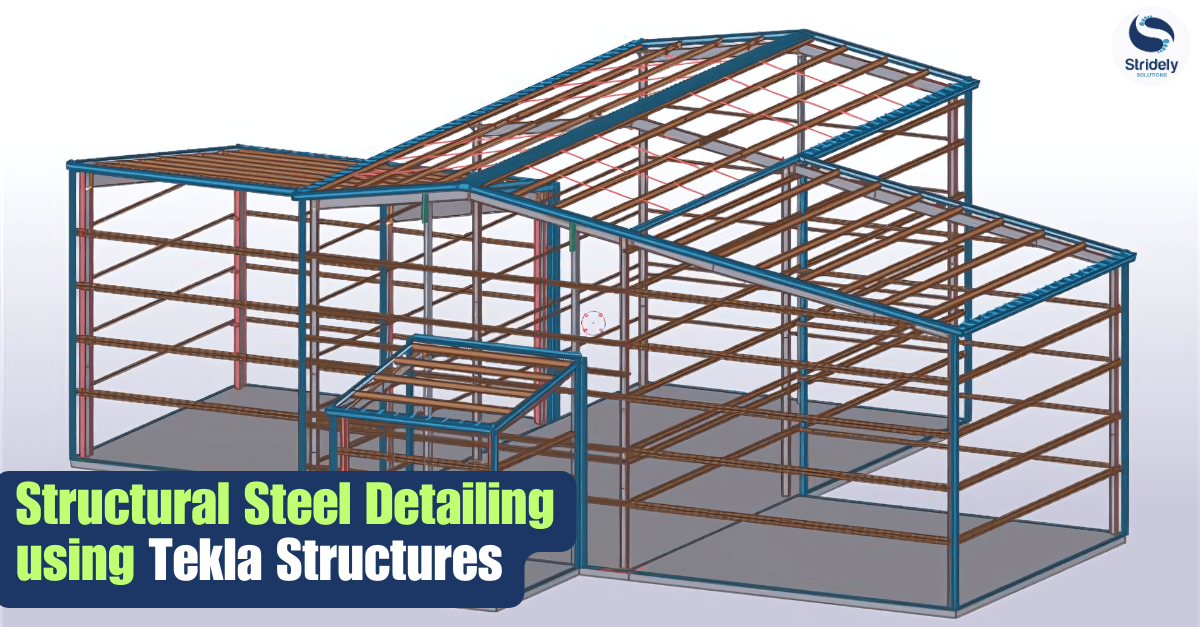

Structural steel detailing is a crucial process in the construction industry, ensuring that buildings and structures are designed with precision and integrity. It involves creating detailed drawings and models that guide the fabrication and erection of steel members, ensuring they fit together perfectly and meet all design specifications.

In the past, structural steel detailing was done manually, which was time-consuming and prone to errors. Today, advanced software like Tekla Structures has revolutionized this process, allowing for more accurate and efficient detailing.

Tekla Structures is a comprehensive Building Information Modeling (BIM) software that enables detailers, fabricators, and engineers to create detailed 3D models of steel structures. Using Tekla Structures, detailers can generate detailed shop drawings, erection plans, and reports that streamline the fabrication and construction process.

This guide will walk you through the essentials of structural steel detailing using Tekla Structures. Let’s dive into it.

What is Structural Steel Detailing?

Structural steel detailing is the process of creating detailed drawings and plans for steel fabricators and erectors. These drawings include precise measurements and specifications that ensure each steel component fits together correctly during construction. The primary goal of steel detailing is to provide clear and accurate instructions for the fabrication and erection of steel structures.

Learn More – Tekla Open API: Customizing Tekla Structures for Streamlining of Steel Fabrication Workflows

Steel detailing plays a critical role in the construction process, as it bridges the gap between the design and fabrication phases. Accurate detailing ensures that the steel structure is built according to the design specifications, minimizing errors and reducing the risk of costly rework.

Overview of Tekla Structures

Tekla Structures is a powerful BIM software designed specifically for structural engineering and construction. It offers a range of features that facilitate the creation of detailed and accurate 3D models of steel structures.

Key features of Tekla Structures include:

- 3D Modeling

Tekla Structures offers intelligent 3D modeling capabilities, facilitating accurate visualization of structures and early clash detection.

- Detailing and Drafting

The software automates the creation of detailed shop drawings and construction documentation, reducing manual effort and minimizing errors.

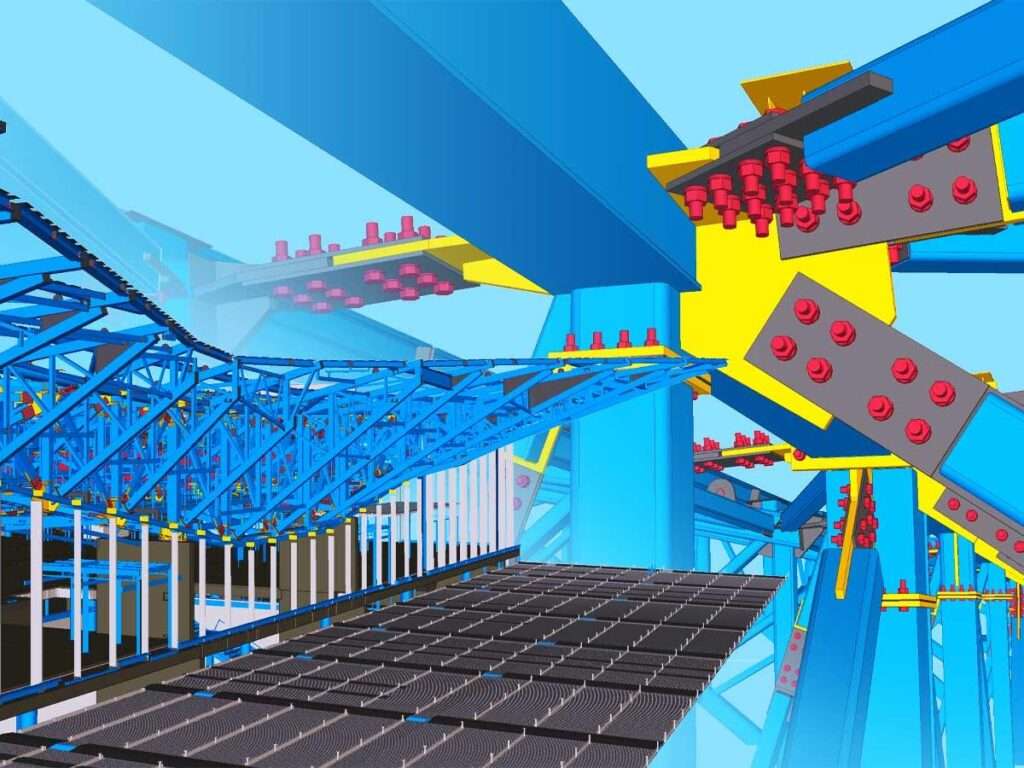

- Connection Design

Tekla Structures includes robust tools for designing and detailing connections between structural elements. This is critical for ensuring the integrity and strength of the overall structure. Users can design complex connections and customize them to meet specific project requirements, ensuring that all connections are both structurally sound and efficient to fabricate.

- Clash Detection

Tekla’s clash detection feature helps identify potential conflicts in the design phase, preventing issues during fabrication and construction. This proactive stance helps reduce the need for revisions and promotes a more seamless construction workflow. By resolving clashes early in the design process, Tekla Structures helps avoid costly delays and rework, ensuring that the project stays on schedule and within budget.

Learn More – A Comprehensive Guide to Tekla Rebar Couplers

- Automated Drawing Creation

Tekla automates the generation of fabrication and erection drawings from the 3D model. This not only saves time but also ensures consistency across all documentation, reducing the likelihood of misinterpretations on the shop floor. Automated drawing creation ensures that all drawings are up-to-date and accurately reflect the 3D model, facilitating smooth communication between design and fabrication teams.

- Interoperability

One of Tekla Structures’ standout features is its interoperability with other commonly used software in the construction industry, such as Autodesk, and Revit. This capability facilitates seamless collaboration between different project stakeholders, enabling the smooth exchange of information and integration of workflows.

- Quantity Take-off

Tekla Structures provides precise quantity take-offs, which are essential for accurate cost estimation and project planning. By generating detailed lists of materials directly from the 3D model, the software helps project managers and estimators plan resources more effectively and control project costs with greater accuracy. This feature ensures that all material requirements are accounted for, reducing the risk of overages or shortages.

- Collaboration

The software facilitates seamless collaboration among stakeholders, supporting open standards for data exchange.

- Structural Analysis Integration

Tekla Structures integrates with structural analysis software, streamlining workflow between designers and analysts.

Modeling

- Creating a New Project

- Launching Tekla Structures and navigating to the project environment.

- Initiating a new project and defining project settings.

- Setting up Grids and Levels

- Establishing a grid system to organize the structure.

- Defining levels for floor heights and structural elements.

- Adding Structural Members

- Utilizing Tekla’s modeling tools to add beams, columns, braces, and other structural components.

- Adjusting properties such as section sizes, materials, and connection details.

Connections

- Adding and Customizing Connections

- Accessing the connection tools within Tekla Structures.

- Customizing connection parameters to meet project requirements.

- Using the Connection Library

- Exploring Tekla’s extensive connection library for predefined connection types.

- Importing and modifying connection types as needed for specific project needs.

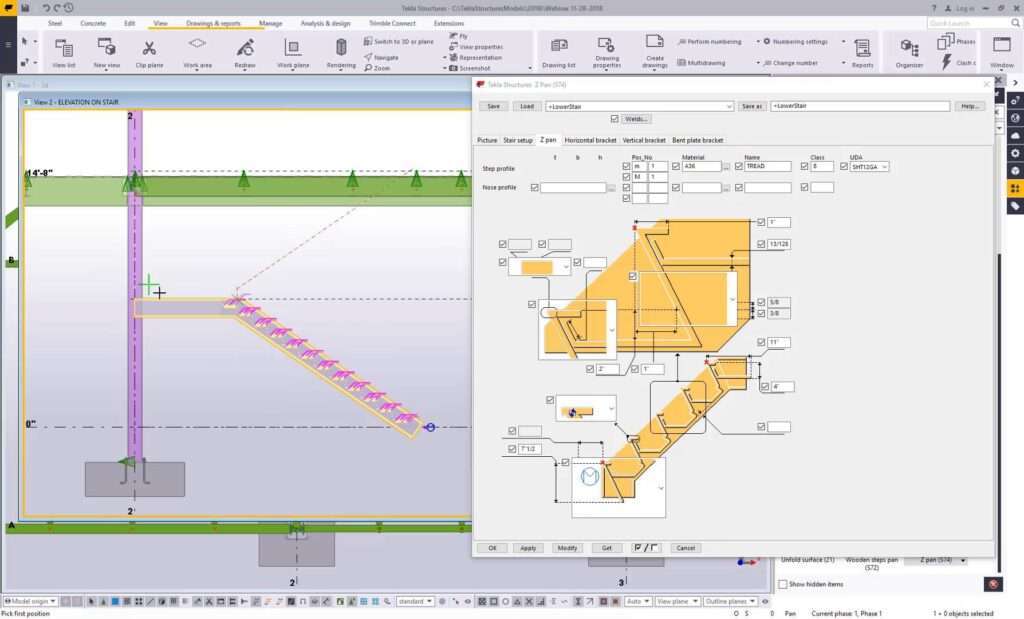

Drawing Production

- Generating Shop Drawings

- Utilizing Tekla’s automated drawing generation tools to produce detailed shop drawings.

- Customizing drawing settings for dimensions, annotations, and views.

- Generating Erection Drawings

- Creating erection drawings to guide on-site assembly and installation.

- Including annotations and dimensions for clarity and accuracy.

- Customizing Drawing Templates

- Modifying drawing templates to align with project standards and preferences.

- Saving customized templates for future use and consistency.

Quality Control

- Checking for Clashes and Errors

- Using Tekla’s clash detection tools to identify conflicts between structural elements.

- Resolving clashes to ensure constructability and integrity.

- Verifying Dimensions and Specifications

- Reviewing dimensions and specifications in the model against design requirements.

- Addressing any discrepancies or inaccuracies to maintain quality control.

Advanced Features of Tekla Structures

Custom Components and Macros

Custom components and macros allow detailers to extend the functionality of Tekla Structures to meet specific project requirements. Detailers can create parametric components and macros that automate repetitive tasks or model complex geometries.

For example, a custom macro might automate the placement of standard connections or generate custom steel profiles. By leveraging custom components and macros, detailers can enhance productivity and streamline workflows.

Learn More – Stridely Revolutionized Construction Modeling and Detailing with Tekla Structures

Automation and Scripting

Automation and scripting capabilities in Tekla Structures enable detailers to automate repetitive tasks and customize workflows to suit project-specific requirements. Detailers can write scripts using Tekla’s scripting language (Tekla Open API) to perform tasks such as batch processing, data manipulation, or custom reporting.

By automating routine tasks and workflows, detailers can improve efficiency, reduce errors, and focus on more complex aspects of the detailing process.

Ending Notes

Tekla Structures stands as a cornerstone in structural steel detailing, offering a comprehensive suite of features that empower detailers to create precise and efficient models. From modeling and connection design to drawing production and quality control, Tekla Structures empowers detailers to create detailed and accurate 3D models that serve as the foundation for successful construction projects.

As a Trimble Tekla partner, Stridely Solutions provides expert services in Tekla Structures and Tekla API, ensuring clients have access to top-tier support and expertise. Contact us to know more.