In the world of engineering & construction industry, innovation serves as a mainstay of progress and evolution. From the development of advanced materials to the implementation of cutting-edge technologies, construction professionals continually strive to enhance efficiency, sustainability, and safety across every facet of their projects.

Since past few years, Tekla has emerged as a transformative force, revolutionizing traditional practices, and setting new standards for efficiency and precision. Developed by Trimble, Tekla’s suite of software solutions has redefined the way construction projects are planned, executed, and managed.

From structural analysis to detailing and project communication, Tekla’s comprehensive platform empowers teams to navigate the complexities of modern construction with confidence and ease.

In this blog, we will delve into rebar couplers, exploring the role of Tekla Rebar Couplers alongside advancements in Artificial Intelligence (AI) in shaping the future of the construction industry.

Reinventing Rebar Connections

Rebar couplers, also known as mechanical splices, are components crucial for connecting two reinforcing bars in a longitudinal direction, offering a seamless solution for ensuring continuous reinforcement over long expanses, extending reinforcing bars, or replacing damaged sections. They play a vital role in any construction project, enhancing efficiency and structural integrity.

Now, you may be wondering how there’s a connection between Reinforcement bar and Rebar Couplers. Well, let’s shed some light on it.

Reinforcement bars, commonly known as rebars, play a crucial role in reinforcing concrete structures to withstand tension and compression forces. The connection between reinforcement bars is vital for ensuring structural integrity and longevity. Rebar couplers serve as a fundamental component in this connection process. By providing a mechanical connection between two rebars, couplers eliminate the need for time-consuming and labor-intensive processes like lapping or welding.

Case Study – Engineering Design and Load Analysis System for the Manufacturing Industry

What is the role of Tekla in Rebar Couplers?

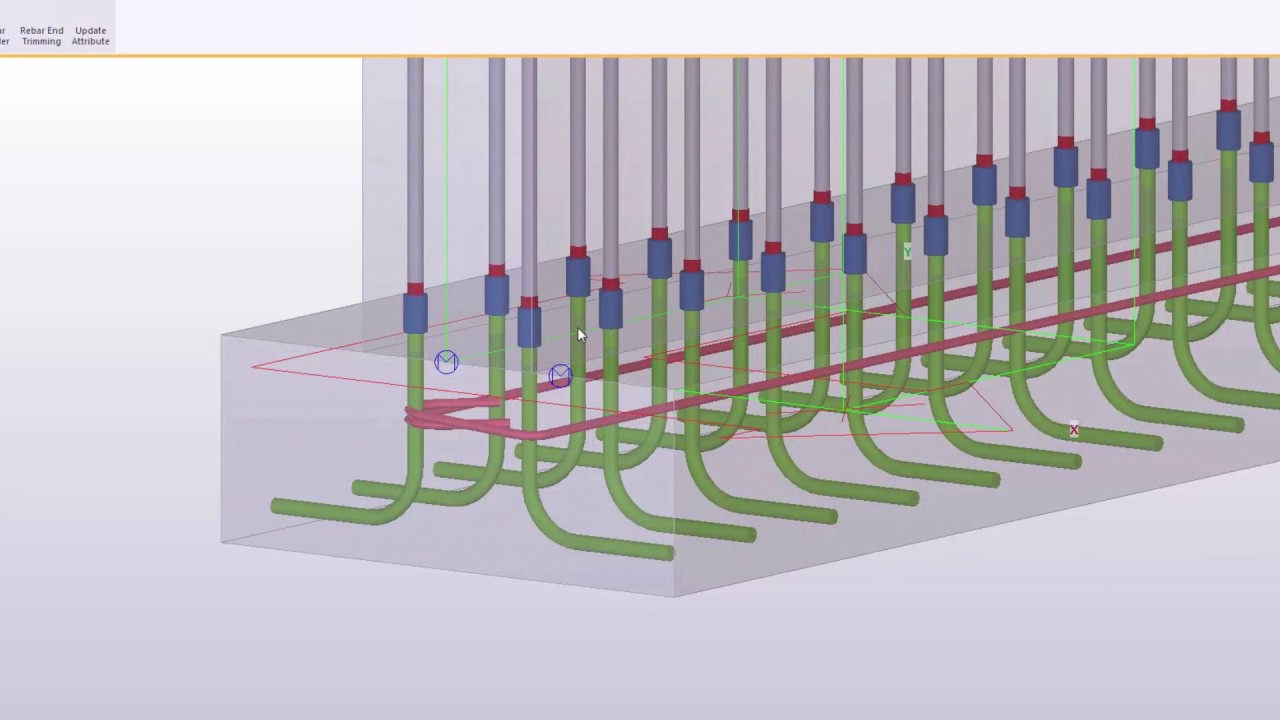

Tekla’s influence in the integration of rebar couplers within reinforced concrete structures is profound. Through its advanced modeling capabilities, Tekla Structures enables precise detailing and positioning of couplers within the 3D model of the structure, ensuring optimal alignment and spacing. This facilitates efficient coordination among stakeholders and streamlines communication regarding coupler placement, ultimately enhancing project efficiency and reducing errors. Additionally, Tekla’s ability to generate detailed drawings and schedules supports accurate fabrication and installation of reinforcement components, including couplers, leading to improved construction quality and timely project completion.

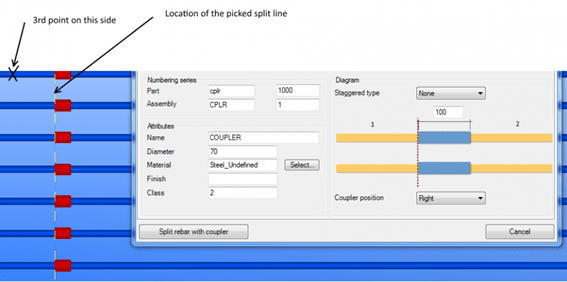

Splitting Rebar and Adding Couplers in Tekla: A Step-by-Step Guide

To split rebar and add couplers effectively in Tekla, follow these simple steps:

- Double-click Split rebar and add coupler to open the component properties.

- Click Split rebar with coupler.

- Select the reinforcing bar, bar group, or rebar set to be split.

- Pick the first split point.

- Pick the second split point.

This point defines the line at which the bars are split and couplers are inserted.

- Pick the third point.

This point defines the side of the primary bars. This is needed if the primary and secondary bars have different properties.

- Repeat the steps 3 – 6, or press Esc to cancel picking.

Tekla Rebar Detailing

Working with Tekla software represents a smarter and more efficient approach to rebar detailing and fabrication within the construction industry. By leveraging Tekla’s powerful tools and functionalities, construction professionals can enhance communication, and coordination, leading to improved productivity in the assembly and construction of reinforced concrete structures.

Tekla’s 3D modeling environment serves as a cornerstone of efficiency, automating repetitive detailing and documentation tasks with unparalleled precision. This intuitive platform simplifies the management of rebar assemblies, ensuring that construction-quality information is readily available for reporting and material handling.

One of the most significant advantages of Tekla Rebar Detailing is its seamless integration with other software and systems used in the construction workflow. Construction professionals can effortlessly export data to rebar MES software, as well as cut-and-bend and mesh welding systems, streamlining the fabrication process and optimizing material usage.

Furthermore, Tekla’s user-friendly interface and comprehensive documentation tools facilitate the creation of easy-to-understand rebar assembly guides, complete with 3D visualizations. These guides not only reduce Requests for Information (RFIs) but also improve the quality of prefabricated components and streamline rebar placement on-site, resulting in greater efficiency and cost savings throughout the construction process.

Learn More – Stridely Solutions Expands Global Footprint with New Partnership: Welcomes Tekla Canada on Board

Maximizing Efficiency with Tekla Rebar Detailing

With Tekla, detailing rebar structures becomes streamlined and error-free. Key features include:

- 3D Detailing: Detail any structure in 3D, regardless of size or complexity.

- Automated Numbering: Automatically number rebar and generate all necessary documents directly from the model.

- Error Prevention: Tekla helps prevent detailing, documentation, and coordination errors, saving time and resources.

- Efficient Adaptation: Easily adapt to project changes while maintaining efficiency and accuracy.

- Information Management: Tekla enables efficient information management, ensuring data accuracy and seamless transfer according to process needs.

- Enhanced Fabrication and Field Efficiency: Drive efficiency and quality in fabrication and on-site work, saving time and reducing human errors.

AI Advancements in Construction

The integration of Artificial Intelligence (AI) and Machine Learning (ML) is reshaping the construction industry, offering transformative solutions to age-old challenges. The applications of AI and ML in construction are vast, promising to enhance productivity, streamline operations, and improve safety across the board.

- AI-driven predictive models, such as Artificial Neural Networks, analyze project data to forecast cost overruns and optimize project timelines, empowering project managers with proactive decision-making capabilities.

- Generative Design for Building Optimization: AI-powered generative design tools enable efficient planning and design by identifying and mitigating clashes between different models, ultimately minimizing rework and maximizing efficiency.

- Risk Mitigation: AI algorithms monitor and prioritize risks on construction sites, allowing project teams to focus their efforts on mitigating the most critical factors, thus enhancing project resilience and success rates.

- Enhanced Project Planning: AI-driven robots and deep neural networks streamline project planning by autonomously capturing site data, classifying project progress, and optimizing workflows to prevent delays and budget overruns.

- Off-Site Construction: Off-site factories staffed by autonomous robots increase construction efficiency by assembling building components, leaving human workers to focus on detailed finishing work on-site.

Artificial Intelligence in Tekla

Tekla does not have a standalone AI integration within its software suite. However, Trimble has been actively investing in AI and machine learning technologies across various sectors, including construction. While specific AI functionalities may not have been directly integrated into Tekla software, Trimble’s broader initiatives in AI could potentially influence future developments in Tekla’s capabilities. These advancements hold promise for revolutionizing construction processes, driving efficiency, reducing costs, and improving project outcomes. Key advancements include:

- Automated Design Optimization: AI algorithms optimize design parameters for enhanced structural performance and efficiency.

- Predictive Analytics: Tekla’s AI capabilities analyze historical data to predict potential issues and optimize construction workflows.

- Smart Scheduling: AI-driven scheduling tools optimize project timelines, considering various factors to minimize delays and improve efficiency.

- Enhanced Quality Control: AI-powered quality control tools identify errors and inconsistencies in designs, ensuring construction projects meet the highest standards.

- Intelligent Resource Allocation: AI algorithms optimize resource allocation, ensuring materials and manpower are utilized effectively throughout the project lifecycle.

Case Study – Stridely Revolutionized Construction Modeling and Detailing with Tekla Structures

Future Outlook

From the seamless integration of AI and machine learning to the meticulous detailing and fabrication facilitated by Tekla’s robust tools, the platform revolutionizes traditional construction practices. Whether it’s predicting cost overruns, optimizing project timelines, or enhancing safety protocols, Tekla proves instrumental at every stage of the construction lifecycle.

As we navigate the future of construction with Tekla, it’s essential to embrace these technological advancements fully. By harnessing the power of AI, leveraging cutting-edge design tools, and prioritizing innovation, construction firms can stay ahead of the curve and deliver projects with unmatched efficiency and quality.

If you are looking for such revolution in your projects, reach out to Stridely Solutions today. With our expertise in Tekla and commitment to excellence, we’re here to support you in achieving your goals and driving industry-leading innovation.