Oracle ASCP (Advanced Supply Chain Planning) is an internet-based and comprehensive planning solution for enterprises. It decides the work orders, purchase orders, and inventory, which must be deployed within an expansive supply chain. In short, it is the supply planning function.

A part of Oracle E-business suite, it is a web-based application that conducts planning and handles business issues. Oracle ASCP provides a transparent picture of your Supply Chain with supreme ease of decision-making ability. It also helps balance the supply and demand.

Also Read: Market welcomes Supply Chain 4.0 – Is it going to revolutionize the industry?

With multiple advantages, Advanced Supply Chain Planning could be a right thing for your business. Read the article to learn more about Oracle ASCP and figure out if your venture needs it. Let’s get started.

What problem set does Oracle ASCP address?

Oracle ASCP addresses the following significant supply planning challenges, which are shown below:

- How do you involve your trading partners?

- How can you keep optimizing your plans?

- How can you access your plan from anywhere?

- How can you plan all the required manufacturing methods and standards?

- How do you plan the supply chain in the shortest time span?

- How can you plan your entire supply chain?

- How do you reduce the number of executions and iterations?

What are the competencies of Oracle ASCP?

The key capabilities are shown below:

● Limited Capacity Planning and Scheduling

Oracle ASCP produces feasible supply chain plans, which consider both material and resource constraints.

● Holistic Planning, Optimizations, and Scheduling

Oracle ASCP can fruitfully plan all the supply chain amenities. Long-term and short-term aggregate and precise scheduling are supported within a single plan.

Therefore, such plans also uphold numerous multiple manufacturing methods. These include flow, discrete, process, and project manufacturing.

● Worldwide Accessibility

The database-oriented architecture of Oracle ASCP preserves plan data in a central planning server database. Such data could be accessible from anywhere through a simple browser. Numerous planners can access data from a single plan quickly.

● Workflow-oriented Exception Messaging

The exception messages feature of Oracle ASCP alerts planners to crucial challenges throughout the extended supply chain.

Workflows, which propel such exceptions, route data to and feedback from trading partners as mandated. Therefore, it efficiently involves them in the supply chain planning procedure.

● Optimization

Businesses can rapidly configure Oracle ASCP to improve particular organizational criteria. No programming is that much necessary to access the robust mathematical optimization competencies of the Oracle ASCP.

● Combined Planning and Execution

The advanced planner workbench user interface of Oracle ASCP both showcases display plan results and enables planners to conduct planning recommendations. The planners don’t have to shift to the transaction system to operate plan execution.

● Backward Compatibility

The component architecture of Oracle ASCP allows it to be exploited against any version of the Oracle transaction systems.

● Simulation Capability

Oracle ASCP enables ongoing changes to demand, supply, resource profiles, and plan options to imitate changing business conditions. You can produce a top-notch plan in terms of all the changes that have been entered through the planner’s workbench.

Countless scenarios could be imitated and compared, harnessing copy plans, online planning, and exceptions. Some of the crucial changes are:

- Changing sources

- Firming

- Modifying priorities

- Rectifying resource availability, objective weights, and varying sources.

Oracle ASCP Process

The process of Oracle ASCP starts when we accumulate the transactional data from the Oracle E-business Suite. Therefore, it accomplishes specific changes according to the planning recommendations.

Collections

The collection procedure in Oracle ASCP is identified as the process of shifting data from the transaction instance to the planning instance. Therefore, the transaction source could be an Oracle E-business Suite/JD Edwards/SAP or any ERP system. However, some primary target and collection standards are the following:

- Target refresh

- Complete refresh

- Net-transformation refresh

Plans

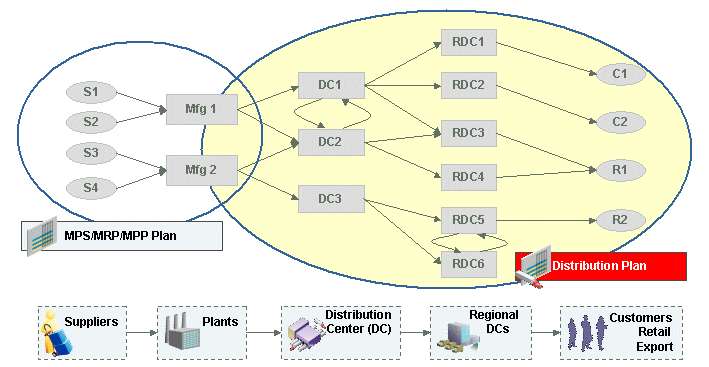

In Oracle ASCP, businesses can produce distinct plans. These are constrained and unconstrained plans. Hence, these enforce demand due dates, competency constraints, decision rules, and a developed plan. Diverse options of ASCP planning are shown below:

- Master Production Scheduling (MPS)

- Master Requirement Planning (MRP)

- Master Production Planning (MPP)

What are the major functionalities of Oracle Advanced Supply Chain Planning?

Oracle ASCP is the best-in-class planning engine that empowers you in making effective decisions. It carefully plans your end-to-end supply chain management procedure utilizing a single plan.

The procedure initiates when users can feel the demand, and then they mold it while comparing the planned demand to the actual one. Therefore, in order to plan something using ASCP, it can incorporate all the distribution and production enterprises. That’s why it is hassle-free to prepare all the mandated organizations.

The crucial functionalities, which Oracle ASCP provides are following:

- Using ASCP, enterprises can feel the requirement, which their customers and users produce. This is how they may respond to the provision by differentiating the planned demand from the real one.

- Oracle ASCP possesses an extraordinary and propagated workbench. It provides planners with a hassle-free way to prepare, evaluate, change, launch, and edit the plans simultaneously.

- Enterprises can receive workflow-produced exception alerts and messages in a notification summary.

- Integration with other ERP systems offers the optimal level of planning. Therefore, it eventually provides superiority in the supply chain management process.

- Using Oracle ASCP, organizations can acquire demand-oriented planning and curtail the potential risks and threats, which may emerge during planning.

- It works on analytical processing. Therefore, it offers real-time feedings of demand. Hence, they can respond to the demand within zero time due to the availability of holistic supply planning.

Architecture and Design of Oracle ASCP

The Oracle ASCP is precisely structured and designed to fulfill intricate demands in real-time. Therefore, it provides an elevated performance deployment because of the below-mentioned features:

- Multi-thread snapshot

- Combination with legacy systems

- Process-oriented memory allocation

- Supreme ease of integration with this Oracle E-Business Suite

- Centralized database for seamless and rapid access from anywhere

- Hot backup and recuperation available

- Materialized view

Oracle Advanced Supply Chain Planning effectively combines with the Oracle E-business Suite/JD Edwards so that data is seamlessly transferred to Oracle ASCP using XML.

Source: Oracle

In addition, Oracle ASCP provides features such as KPIs, workflows, wherein plans are developed, all of which provide enhanced planning capabilities. So, customers, users, and suppliers can interact by harnessing their respective logins.

Oracle ASCP’s Processing Flow

This process begins with the new plan generation and finishes at implantation on the source instance. However, it is recommended to first build a brand-new plan in Oracle ASCP, which consists of the details that suit the business. This new plan is then launched so as to make it available for the planner to execute planning. In the subsequent phase, planning engines are evaluated and applied to the source instance.

Innovation of a Plan

Oracle ASCP helps enterprises to create a plan in this phase. In terms of your business requirements, it may select a plan that corresponds to your work ambiance.

However, the plan may contain vast numbers of safety stocks in the inventory, delivery, and inventory scheduled on accurate time and date.

Launching that Plan

In this phase, Oracle ASCP will launch this brand-new plan to ensure availability in the planner’s workbench. Therefore, it can conduct evaluation and adjustment on a plan basis. Thus, the existing supply and requirements are available during the launching of the plan.

However, all these needs are available from the source instance and adjustments, which could be accomplished using the result-driven approach.

Evaluation and Adjustments

Plan assessment is mainly done in terms of the KPIs. In this step, Oracle helps make the adjustments while getting the plan recommendation.

This is how the supply and demand procedure will change accordingly. In order to acquire the most out of the proposal, Oracle runs the plan in a simulation mode.

Implementation of the Analysis

In this key phase, Oracle ASCP makes the fundamental changes in the transactional data to explain a precise and optimal process.

Planning with Oracle ASCP in diversified organizational environment

Utilizing Oracle ASCP, distinct sorts of planning can be accomplished for diverse business types. If you are in a manufacturing company, which produces end products using its superior manufacturing procedure, or you are in a distribution organization, which distributes merchandise.

Therefore, it can be manufactured within the company or end products bought from other enterprises for distribution. So, in Oracle ASCP, users can acquire uniquely crafted plans for both types of companies in an isolated way. Therefore, in case you are both in a distribution and manufacturing organization, you can execute planning for your enterprise using this Oracle ASCP. The major types of usable plans are following:

Master Production Scheduling (MPS) and Material Requirements Planning (MRP) are used for manufacturing purposes. Here, anyone can schedule and streamline the production process. Next, Distribution Plans (DRP) are used for only distribution purposes. These plans are propelled by the material requirement plan and production scheduling plans.

Concluding words

The above article elaborates the objectives of Oracle ASCP and its advantageous for enterprises. The article demonstrates how supply and demand are managed, and how it can balance the production, purchase, and sales using the Oracle ASCP suite. If you are looking for professional help in deploying Oracle ASCP for your company, our Stridely Oracle experts are readily available.