To meet demand in a challenging market, you need automated, flexible manufacturing processes that support risk-resilient and sustainable operations.

SAP Manufacturing, a robust suite of tools designed to meet the unique demands of modern production environments. Far from mere software, SAP Manufacturing represents a strategic ally for industries grappling with the complexities of today’s manufacturing landscape.

In this blog, we will delve into three key products under SAP Manufacturing—SAP MES, SAP MII, and SAP DMC. We will discuss key differences in all three. These products not only tackle the challenges at hand but also set the stage for a more resilient, responsive, and efficient manufacturing future.

Given the array of options, it’s understandable if you feel a bit like navigating a complex puzzle. Don’t worry—this blog is here to guide you through these products, identifying the differences and helping you make an informed decision.

Learn More – SAP Manufacturing Solutions

SAP Manufacturing Products Overview:

Before diving into the difference, let’s first understand what different products SAP has under manufacturing:

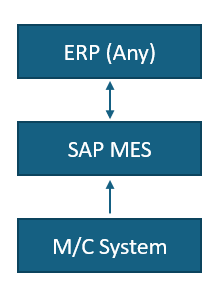

SAP MES (Manufacturing Execution System): At the heart of SAP’s manufacturing arsenal, MES orchestrates real-time production processes. It optimizes operations from planning to execution, ensuring seamless coordination and adherence to quality standards. MES enhances visibility into shop floor activities, minimizing downtime, and boosting overall production efficiency.

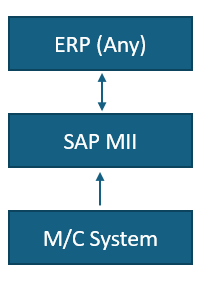

SAP MII (Manufacturing Integration and Intelligence): Functioning as connective tissue, MII integrates diverse manufacturing components, providing a real-time data interface. It transforms raw data into actionable intelligence, empowering decision-makers with insights into production dynamics. MII ensures timely responses to changing conditions, fostering an agile and informed approach to manufacturing.

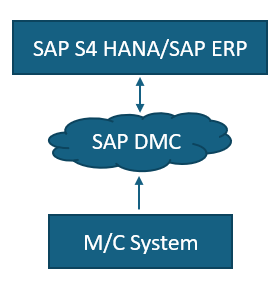

SAP DMC (Digital Manufacturing Cloud): In the dynamic landscape of modern manufacturing, DMC stands out for its real-time control and adaptability. DMC enables quick adjustments to production processes, responding to fluctuations in demand, supply chain dynamics, and unforeseen disruptions. DMC ensures that manufacturing remains agile, allowing businesses to navigate uncertainties while maintaining operational efficiency.

Key Differences Between SAP MES, SAP MII, and SAP DMC

Understanding the distinct functionalities of each product—SAP MES, SAP MII, and SAP DMC—is crucial for making informed decisions tailored to your business needs. Let’s delve into the specific characteristics that set these three apart.

PRIMARY |

|||

| APPLICATION | SAP MES | SAP MII | SAP DMC |

| DEFINITION | SAP MES optimizes manufacturing by monitoring, documenting, and controlling the entire production lifecycle. | SAP MII is an integration platform connecting manufacturing systems, offering tools for data acquisition, analysis, and process control. | SAP DMC, a cloud-based platform, manages the digital manufacturing process with tools for production schedules, line monitoring, and quality tracking. |

| FEATURES |

|

|

|

| BENEFITS |

|

|

|

| Application Architecture |  |

|

|

Learn More – SAP Business One for Manufacturing: Key Features and Guide

SECONDARY |

|||

| Use of System | System helps, manage, and monitor production process on shop floor | Used for production process plus focus on collecting and analyzing data | Monitor the entire manufacturing process to optimize resources and execution. |

| FUNCTIONS | Production scheduling, material tracking, quality management and performance analysis | Integration data from different system to create unified view of production operation | Tracking actual production progress against planned production with order-specific details, Visualizing an overview of resource availability and associated availability losses. |

| DESIGNED FOR | Optimize production process and improve efficiency | SAP MES functions plus real time data visibility on manufacturing process and real time decision making | MES & MII functions plus monitor overall manufacturing process & react quickly for unexpected events, monitor overall equipment effectiveness (OEE) |

|

SOLUTION Usability |

Helps in manufacturing to manage production process in real time from planning to execution | Helps manufacturing integrate manufacturing system and data sources, make data driven decision based on the real time data from operation | Live monitoring provides near real-time analytics, Operational analytics capability offers prebuilt reporting apps as well as a self-service environment to build manufacturing KPIs and dashboards using embedded SAP Analytics Cloud. |

| FOCUSED | On managing production process | With managing production process, it collects and analyzing data to provide insights into that process | With managing production process & data analyzing, manage downtime events, too. |

| MODULES | Production scheduling, job management, quality management and inventory management | Customized solution, Manage manufacturing operation by integration, visualization, analysis, execution plant connectivity, business integration, manufacturing intelligence | MES Plus 3D visualization of object, Manage operations, Plant Connectivity, usage & defect recording |

| Integration Layer | At Top level it connects with any ERP via IDOC, BAPI, Webservices and Java Connectors and bottom it connect with M/c System via PCo connection | At Top level it connects with any ERP via IDOC, BAPI, Webservices and Java Connectors and bottom it connect with M/c System via PCo connection | At Top level it connects with S/4HANA or SAP ECC via Cloud Connectors and bottom it connect with M/c System via PCo connection |

| Deployment option | Available on Premises and with Private cloud | Available on Premises and with Private cloud | Only with Public cloud |

Which solution should you choose?

Selecting the right product is pivotal for optimizing operations. Let’s delve into the unique strengths of each product:

SAP MES (Manufacturing Execution System):

Unique Features:

- Streamlined Efficiency: Excels in centralizing operations for enhanced shop floor efficiency.

- Real-time Data Control: Focuses on automated data collection for accurate and available real-time data.

- Immediate Issue Resolution: Enables prompt detection and resolution of issues, minimizing downtime.

Why Consider MES?

SAP MES is uniquely tailored for organizations seeking standardized processes, real-time production insights, and improved operational efficiency at the shop floor level.

Learn More – S/4HANA Upgrade (Technical, Functional upgrade and Fiori upgrade)

SAP MII (Manufacturing Integration and Intelligence):

Unique Features:

- Unified View: Provides a centralized plant information system for comprehensive insights.

- Holistic Analytics: Focuses on enhanced overall equipment effectiveness and specialized manufacturing analytics, seamlessly integrating into broader business processes.

Why Consider MII?

SAP MII stands out for organizations aiming at improved user experience, time and cost savings, heightened data security, and a need for real-time integration.

SAP DMC (Digital Manufacturing Cloud):

Unique Features:

- Operational Agility: Designed for manufacturing automation, enabling quick adjustments to production lines for operational flexibility.

- Resource Optimization: Ensures optimal use of manufacturing resources through efficient resource management.

Why Consider DMC?

SAP DMC uniquely suits organizations prioritizing ease of use with an intuitive interface, a cloud-based platform for reduced upfront investment, pre-built applications for rapid deployment, and robust analytics for valuable insights.

Make the Right Choice for Your Manufacturing Needs

If you’re still grappling with the decision on the right manufacturing product, clarity is just a step away. Forget the confusion and reach out to Stridely Solutions. Our experts are ready to guide you in selecting the right product that perfectly aligns with your organization’s needs. Let’s simplify the decision-making process together!